Fabrication

Steps for Fabrication:

About Paint Process:

Our HSSE Vision is one of the main priorities we are concerned about. You can easily prevent yourself from all types of accidents. Our aim is involved in the excellent HSSE performance in all the business categories. We will be serving the high-quality neighbors & community using protecting their lives and environment.

Our Main HSSE KPIs are as mentioned below:

Third Party Inspection:

FABRICATION

(FABRICATION PROCESS)

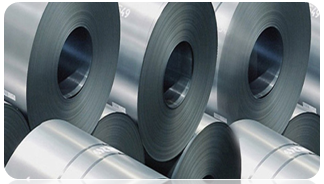

M.S. Sheets OEM

Manufactured Parts & Documents (OEMs)

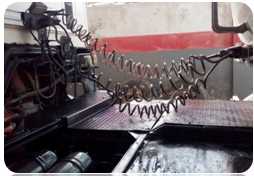

Marking & cutting/rolling/pressing/drilling work

Safety & Security

Fit up joints

Fit up inspection

Welder Qualification Certificate

Welding quality

Safety Checks of Complete Welding

Water Filling Test

PAINT PROCESS

Surface Preparation

Paint Process (MSDS)

Electric Work

FINAL INTERNAL INSPECTION CHECKLIST

Third Party Inspection

Certifications

- It involves the Raw Material(MTC)

- It also has the Manufacturing Documents(OEMS)

- It is presenting upon the Marking & Cutting(cutting as per design)

- Fabrication Welding is part of it.

- It brings safety and security measures.

- It has fit up joints.

- It has fit up Inspection

- Welder Qualification Test(WQT)

- Welding Quality

- Safety checks of Complete welding are also considered

About Paint Process:

- It carries out Surface Preparation.

- It has Paint Process & Docs (MSDS)

- Logos & Stickers are also printed.

Our HSSE Vision is one of the main priorities we are concerned about. You can easily prevent yourself from all types of accidents. Our aim is involved in the excellent HSSE performance in all the business categories. We will be serving the high-quality neighbors & community using protecting their lives and environment.

Our Main HSSE KPIs are as mentioned below:

- Daily toolbox meeting

- Monthly safety meeting

- PI’s reporting

- Training of both staff and drivers.

Third Party Inspection:

- Visual Inspection

- Functional Test

- HSE Rating

- Hydro Test

- Inspection Report

FABRICATION

(FABRICATION PROCESS)

M.S. Sheets OEM

Manufactured Parts & Documents (OEMs)

Marking & cutting/rolling/pressing/drilling work

Safety & Security

Fit up joints

Fit up inspection

Welder Qualification Certificate

Welding quality

Safety Checks of Complete Welding

Water Filling Test

PAINT PROCESS

Surface Preparation

Paint Process (MSDS)

Electric Work

FINAL INTERNAL INSPECTION CHECKLIST

Third Party Inspection

Certifications